In this article

- Key Factors in Evaluating Rock Climbing Wall Manufacturers

- Expert Reviews: Profiling Top Rock Climbing Wall Manufacturers

- Walltopia: Global Innovator and Turnkey Solutions Provider

- Rockwerx: North American Durability and Gym Business Consulting

- EP Climbing (Entre-Prises): Olympic Pedigree and Global Expertise

- Eldorado Climbing (Eldowalls): U.S. Leader in Customization and Accessibility

- Vertical Solutions: Master of Aesthetic Wood Designs

- Nicros: Diverse Systems and Comprehensive Safety Programs

- Citywall: Sustainable European Innovation with Glulam Structures

- Navigating Your Manufacturer Selection Journey: A Buyer’s Guide

- Future Outlook: Innovations Shaping Climbing Wall Manufacturing

- Conclusion: Choosing Your Ideal Climbing Wall Partner for Long-Term Success

- Frequently Asked Questions about Rock Climbing Wall Manufacturers

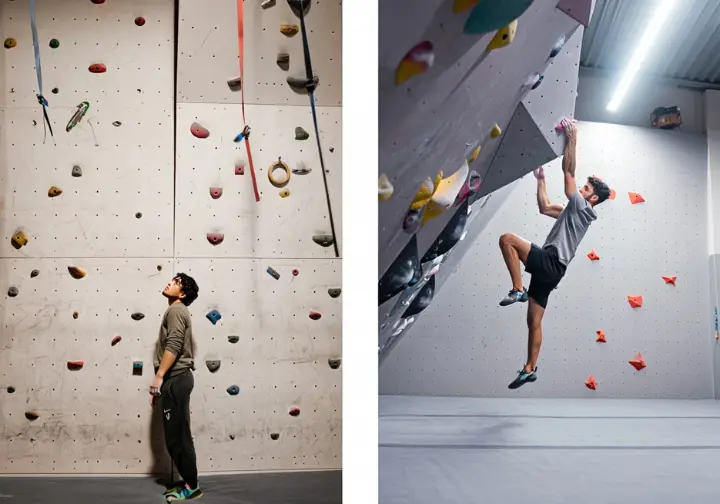

The world of indoor climbing has seen remarkable growth, fueling a strong demand for expertly designed and resilient rock climbing walls. A climbing wall isn’t just a structure; it’s the heart of a climbing facility, pivotal for ensuring climber safety, delivering satisfaction, and shaping the gym’s brand. This article delves into key evaluation criteria for rock climbing wall manufacturers, offers in-depth reviews of leading companies, and provides strategic advice for those looking to invest in new climbing walls. We aim to equip you, whether a dedicated climber or facility planner, with the insights to navigate the climbing industry and make choices that elevate your climbing environment. Let’s explore the creators behind these vertical playgrounds.

Key Factors in Evaluating Rock Climbing Wall Manufacturers

Choosing the right rock climbing wall manufacturer is a significant decision when planning to build a gym. This section breaks down the essential criteria to assess and compare different companies. Understanding these factors helps select a partner that aligns with your facility’s specific needs, budget, and long-term vision for your climbing gym, ensuring a well-rounded evaluation.

Breadth and Depth of Product Offerings

A manufacturer’s capacity to provide a wide array of wall types often reflects their experience and ability to serve diverse market segments. This includes everything from bouldering walls and top-rope structures to IFSC-certified speed climbing walls, specialized children’s climbing areas, and training-specific installations like Kilter Boards or MoonBoards, as well as modular systems for smaller or flexible spaces. Some companies, like Walltopia and EP Climbing, showcase extensive portfolios covering nearly every climbing discipline, including lead climbing and competition climbing structures, sometimes even active entertainment attractions. These wall products demonstrate their versatility.

The availability of specialized solutions, such as walls for adaptive climbing programs or unique architectural integrations, indicates a manufacturer’s deep expertise. This is particularly important for facilities aiming for inclusivity or a distinct brand. When evaluating, consider if they offer comprehensive solutions, including safety flooring, climbing holds, and routesetting, which can simplify project delivery. Exploring the types of climbing walls available can provide a broader perspective, and for those interested in competition standards, reviewing IFSC specifications for competition walls is beneficial. A solid grasp of understanding the different climbing wall components further aids in this evaluation of wall sections and overall wall design.

Material Science, Durability, and Innovation

The materials chosen—such as engineered plywood like Baltic birch, steel frameworks, Glass Fiber Reinforced Concrete (GFRC), or proprietary composites—are fundamental for any climbing wall. They affect a wall’s durability, texture, aesthetic, and maintenance. Different materials offer unique advantages in feel, wear resistance, and suitability for various environments. Many manufacturers pride themselves on using top-tier materials.

Innovative materials or construction techniques, like Vertical Solutions’ hardwood systems or Rockwerx’s GymRock surfaces, can define a gym’s aesthetic and climber experience. Prospective buyers should inquire about material lifespan, warranty specifics, and any durability testing conducted by the manufacturer. The trend towards sustainable and eco-friendly materials is also growing, with companies like Citywall using glulam. Investigating a manufacturer’s commitment to such practices is valuable, as is understanding their approach to product longevity and performance. The materials used for climbing holds also play a role in the overall system, often sourced from specialized hold manufacturers.

Design Philosophy, Engineering, and Customization

A manufacturer’s design philosophy and in-house engineering capabilities are critical for creating climbing walls that are not only visually appealing and challenging but also structurally sound and unequivocally safe. This involves adherence to rigorous engineering principles by qualified engineers to ensure the wall can withstand dynamic climbing forces over many years of use.

The potential for custom climbing wall design is a major factor, allowing facilities to tailor wall angles, walls features, overall geometry, and aesthetics to their specific brand identity, available space, and the skill levels of their target climbers, including experienced climbers. Companies like Eldorado Climbing often highlight their ability in translating diverse client visions into iconic structures. A truly collaborative design process, involving consultations and 3D renderings, is key to aligning the final product with facility goals and maximizing routesetting flexibility for every climb. This includes designing walls for beginner climbers to ensure inclusivity. Ask about their engineering team’s experience and how they ensure customized designs meet safety standards for every new wall.

Commitment to Safety Standards and Certifications

A manufacturer’s proven commitment to safety, through adherence to recognized industry standards and certifications, is non-negotiable when selecting rock climbing wall manufacturers. This impacts user safety, facility liability, and operational integrity. Key standards include the European Standard EN 12572, a comprehensive benchmark for Artificial Climbing Structures. Adherence to standards set by bodies like USA Climbing can also be a factor for facilities hosting competitions.

In the USA, the Climbing Wall Association (CWA) provides the CWA’s General Specification for Design and Engineering of Artificial Climbing Structures, a vital guideline for the climbing industry. While the CWA primarily certifies instructors, reputable builders follow these engineering specifications. Always request detailed documentation of compliance or third-party certifications. Vague claims are insufficient; specific standards and certifying bodies should be identified for a genuinely safe climbing environment. This complements understanding climbing safety rules more broadly.

Installation Expertise and Post-Installation Support

The quality of installation is as critical as the manufactured wall components. Experienced, certified installation teams are essential for correct assembly, secure anchoring, and compliance with engineered designs and safety standards. Climbing wall installation companies should demonstrate this expertise for all various gym builds.

Comprehensive post-installation support, including detailed warranties, maintenance guidelines, and professional inspection services, is a hallmark of reputable manufacturers. Some, like EP Climbing, offer post-installation services including inspections. This long-term relationship is invaluable. Inquire about installer qualifications, quality control during installation, and typical timeframes. Many facilities also adhere to CWA guidelines for facility inspections to maintain safety. This diligence parallels the importance of maintaining climbing safety gear for individual climbers. Proper ballistic nylon flooring or other safety surfacing is also a key part of the installed system.

Market Reputation, Project Portfolios, and Client Feedback

A manufacturer’s reputation is built upon its consistent track record of successful projects and satisfied clients. Investigate their project portfolio for examples that are similar in scale, style, and target audience to your own planned facility. Client testimonials, detailed case studies, and any industry awards or recognitions can provide valuable insights into reliability, the quality of their workmanship, their project management capabilities, and their responsiveness to customer needs and concerns.

Don’t hesitate to ask for references from previous clients, especially those with projects comparable to yours. Direct conversations can provide candid feedback. Reviewing industry publications, forums, and the manufacturer’s own showcased projects, such as Walltopia’s extensive list which showcases numerous global projects, or Rockwerx’s portfolio of home climbing wall installations, helps build a comprehensive picture of their market standing and capabilities in wall manufacturing.

Expert Reviews: Profiling Top Rock Climbing Wall Manufacturers

This section delivers in-depth reviews of several top-tier rock climbing wall manufacturers. We highlight their unique specializations, core strengths, material philosophies, and notable projects to assist you in making an informed selection for your commercial climbing gym construction or home wall project. These wall vendors represent some of the best in the climbing industry.

Walltopia: Global Innovator and Turnkey Solutions Provider

Walltopia, with global operations including Walltopia Canada, is a dominant leader, known for comprehensive turnkey climbing and adventure solutions. The Walltopia team manages projects from concept through manufacture and installation, even offering active entertainment attractions. Their commitment to innovation is clear with their Lambda-CDM system for digital route sharing.

Their product range for climbing walls is vast, covering bouldering, rope walls, IFSC-certified Speed Climbing Walls, kids’ climbing areas, and sophisticated training boards. Walltopia uses high-quality plywood and steel, with recyclable thermoplastic options for climbing holds, aligning with EN 12572 and Eurocodes. Their vertically integrated model ensures quality control for large projects. Many leading commercial climbing gyms feature their walls Walltopia designed. The Walltopia crew is known for professionalism.

Rockwerx: North American Durability and Gym Business Consulting

Rockwerx, based in Massachusetts, is known for highly durable custom climbing walls in North America, particularly their GymRock wall system offering a seamless, concrete-like surface. They also provide a GymRock Lite plywood alternative. These wallsRockwerx produces are built to last.

A key differentiator for Rockwerx is their consulting service for new climbing gym entrepreneurs, using tools like their GymCalc algorithm program for business planning. Their product range includes custom-designed walls, modular climbing wall systems, natural rock systems, and even innovative transparent climbing panels, catering to a wide array of commercial and recreational needs. Rockwerx has a strong reputation for complex structures, including custom wallsRockwerx tailored for specific client needs.

EP Climbing (Entre-Prises): Olympic Pedigree and Global Expertise

EP Climbing (Entre-Prises) has a rich history since 1985, known for bespoke climbing walls and creating early commercial climbing holds. With a global presence, EP Climbing is an official supplier for IFSC and multiple Olympic Games, making them a key player in competition climbing and sport climbingthe IFSC relies on.

Their flagship systems include MozaiK panels, allowing highly customized wall designs. The TITAN Boulder is an IFSC-endorsed competition bouldering wall. EP demonstrates commitment to sustainability with recyclable climbing holds through Greenholds and ISO 14001 certification. They offer comprehensive services, including inspections, route setting, and training. Their focus on innovations in climbing holds is noteworthy for any climbing gym.

Eldorado Climbing (Eldowalls): U.S. Leader in Customization and Accessibility

Eldorado Climbing Walls (Eldowalls) is a large U.S.-owned climbing wall manufacturer known for customization and creating accessible climbing experiences. Their portfolio includes custom-designed climbing walls, modular climbing wall systems like their Gecko and Chameleon lines, standalone boulders, and DIY climbing panels suitable for home walls or smaller commercial applications.

A notable specialization is outdoor structures for public parks, including adjustable outdoor walls. Significant projects include the Summit Bechtel Reserve project and an accessible climbing wall for the National Ability Center. They offer turnkey climbing facility solutions, integrate TRUBLUE Auto Belays, and emphasize safety, making them a strong choice for designing climbing walls for all abilities.

Vertical Solutions: Master of Aesthetic Wood Designs

Vertical Solutions specializes in high-quality, aesthetically distinctive climbing walls from birch and other hardwoods, offering a unique visual and tactile appeal for any climbing wall. Their systems include ARC (curved lines), MLM (durable geometric), and SLM (cost-effective modular).

Recognized for “superior craftsmanship,” they aim to create visually stunning facilities. They provide consulting for new gym development and offer flooring and climbing holds through their sister company, Proxy Climbing. A notable case is the rapid retrofit of Brooklyn Boulders Gowanus, showcasing their speed. Their systems meet or exceed CWA standards for rock climbing walls.

Nicros: Diverse Systems and Comprehensive Safety Programs

Nicros offers diverse wall systems, from realistic rock simulation to modern plywood panels. Their flagship systems include the A.R.T. Wall GFRC panels, molded from real rock, and NicroLite™, polymer-coated Baltic Birch plywood for their climbing walls.

A key differentiator is their “Engage for Safety” program, including professional climbing wall inspections and CWI certification training. They developed the Auto Belay Safety System™. Nicros has a history of innovation in climbing hold design and states their wall designs are engineered to exceed CWA industry standards. For those interested, we offer more details on climbing wall instructor certification.

Citywall: Sustainable European Innovation with Glulam Structures

Citywall, a Slovenian climbing wall manufacturer with a global footprint, emphasizes quality, sustainability, and durability. A key innovation is using glued laminated timber structures (glulam) for frameworks, combined with Baltic birch panels, for strength and faster installation of their climbing walls. They even offer a mobile boulder.

They offer lead climbing and bouldering walls, mobile climbing walls, adjustable walls, and kids’ modular themes. Citywall also serves as an OEM for hold and volume brands. Their walls are designed with adherence to European Standard EN 12572 and they are ISO 9001:2015 certified, cultivating a “every project is personal” philosophy for each climbing wall build.

Navigating Your Manufacturer Selection Journey: A Buyer’s Guide

This section provides actionable advice for prospective buyers, covering steps from defining project requirements and budget, to posing crucial questions, and understanding contracts, warranties, and long-term service agreements for your climbing wall project. This is vital for aspiring gym owners.

Step 1: Defining Your Project Requirements and Budget

Before engaging any rock climbing wall manufacturers, conduct thorough market research on local demographics, competition, and climbing style preferences (e.g., bouldering focus, roped climbing, training amenities). This informs decisions about facility type and offerings for your gym. Clearly define your facility type (bouldering-only, full-service gym, large-scale climbing center) and its scope, including desired wall heights, total climbing surface area, and the allocation of space to different climbing disciplines.

Develop a comprehensive budget beyond rock climbing wall cost, including building improvements, architectural fees, flooring, climbing holds, ropes, auto belays, staff training, marketing, and operational costs. For additional insights, the Climbing Business Journal offers guidance on selecting manufacturers. Learning how to start a climbing gym can also provide foundational knowledge for this stage. Effective planning your indoor climbing facility is a critical first step.

Step 2: Asking the Right Questions to Potential Manufacturers

Engage potential manufacturers with targeted questions. Inquire about their experience with projects similar to yours and ask for references. Request detailed material specifications, their rationale, expected lifespan, and maintenance requirements. This helps in choosing the right climbing wall manufacturer for your climbing gym.

Ask which engineering standards (e.g., CWA General Specification, EN 12572) their walls meet and request compliance documentation. Clarify what’s included in their standard proposal and what services are add-ons. Understand their project timeline and how they manage delays. Everlast Climbing provides a useful list of questions to ask wall builders. This process is akin to evaluating climbing gym facilities from a user’s perspective.

Step 3: Navigating Contracts, Warranties, and Long-Term Support

The relationship with a climbing wall manufacturer extends beyond installation; careful attention to contractual details is vital. Ensure contracts are comprehensive, defining scope, deliverables, timelines, payment schedules, material specifications, and responsibilities. Legal counsel review is advisable before building your climbing wall.

Scrutinize warranty terms: what’s covered, duration, conditions, and exclusions. Evaluate ongoing maintenance and inspection services, as regular professional checks are crucial for safety and upholding warranties for your rock climbing wall. Understanding how to go about maintaining a climbing wall is key, and for broader context, Gubbies Blog offers a guide to operating and inspecting climbing facilities. This mirrors the importance of understanding equipment lifespan and warranties for personal gear.

Future Outlook: Innovations Shaping Climbing Wall Manufacturing

This section delves into emerging technologies, sustainability initiatives, and evolving design philosophies shaping the next generation of rock climbing walls. These trends in climbing wall design offer a glimpse into the future of indoor climbing experiences and the broader climbing industry.

The Rise of Interactive and LED-Integrated Training Walls

Standardized LED-integrated training boards like Kilter Board and MoonBoard are increasingly prevalent in climbing gyms, offering app connectivity and vast problem libraries. Manufacturers are designing adjustable angle boards compatible with these systems or developing their own integrated solutions. Climbing Magazine offers reviews of popular standardized LED training boards. These make for a fantastic climbing wall experience.

Fully interactive climbing walls, like Eldorado Climbing’s COLAB system, integrate gaming mechanics and visual feedback onto larger climbing surfaces. Sophisticated spray wall applications and digital route sharing platforms, such as Walltopia’s Lambda-CDM, aim to create global platforms for route management. There are even apps for spray walls that enhance this experience. These represent significant innovations in climbing training equipment.

Driving Sustainability: Eco-Friendly Materials and Practices

Environmental responsibility is increasingly influencing wall manufacturing towards sustainable materials and eco-conscious processes. Examples include EP Climbing’s collaboration for 100% recyclable climbing holds (making them a notable hold manufacturer) and Walltopia’s recyclable thermoplastic macros. Details on VOC-free paints in manufacturing are available from some companies.

Sustainable sourcing for primary materials, like Citywall’s use of glulam from sustainable forestry and the preference for FSC-certified wood, is important for modern climbing walls. Durability is also key to sustainability, reducing waste. Nicros even offers playground boulders made with corn/soy-based resin. Other practices include waste reduction and energy-efficient manufacturing.

Evolving Wall Designs for Enhanced Climber Experience and Training

Modern wall design trends towards cleaner aesthetics with large, flat, or subtly angled sections. This gives routesetters more freedom when creating a climb. Climbing Business Journal notes a move towards cleaner wall styles for routesetters. Continuous innovation in climbing hold and volume design provides an expanding toolkit for creating varied climbs.

Wall design is becoming more nuanced for different climbing disciplines (e.g., dynamic movements for bouldering, endurance-focused lines for lead climbing, standardized angles for speed climbing) and the varied skill levels of gym patrons. This includes designs tailored for beginners, youth programs, adaptive climbers, and elite athlete training, sometimes influenced by IFSC requirements for competition walls. Adjustable angle walls also reflect a design evolution for maximizing training versatility. These evolving wall designs enhancing bouldering experiences are a notable trend in bouldering gyms.

Conclusion: Choosing Your Ideal Climbing Wall Partner for Long-Term Success

Selecting a rock climbing wall manufacturer is a foundational decision impacting your facility’s success, safety, brand, and climber satisfaction. Reflect on which company’s strengths—be it Walltopia’s global innovation, Rockwerx’s startup consulting, EP’s competition climbing expertise, Eldorado’s accessibility focus, Vertical Solutions’ wood aesthetics, Nicros’ safety programs, or Citywall’s sustainable glulam for their climbing walls—best align with your vision.

Prioritize overall quality, climbing wall safety standards, a collaborative relationship, and long-term value over the lowest initial bid. Conduct thorough due diligence using the criteria and insights from this article to make an informed decision. Our aim is to foster a deeper understanding across all facets of climbing, including the critical infrastructure that supports our sport climbing and bouldering passions.

Frequently Asked Questions about Rock Climbing Wall Manufacturers

What are the most important safety standards I should look for in a climbing wall manufacturer? >

How much does a commercial rock climbing wall typically cost, and what factors influence the price? >

What is the general difference between a custom-designed wall and a modular wall system? >

How long does the process of designing, manufacturing, and installing a climbing wall usually take? >

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. As an Amazon Associate I earn from qualifying purchases. We also participate in other affiliate programs. The information provided on this website is provided for entertainment purposes only. We make no representations or warranties of any kind, expressed or implied, about the completeness, accuracy, adequacy, legality, usefulness, reliability, suitability, or availability of the information, or about anything else. Any reliance you place on the information is therefore strictly at your own risk. Additional terms are found in the terms of service.